| String

Tying

Helpful Hints before you start.

- When you're replacing the highest strings, you may have noticed

that it is difficult to find the string hole from inside the sound

box. One thing you can do is, before you tie your end knot, thread

the string through the soundboard hole from the front of your soundboard.

Pull the string through the back sound holes and then make your knot.

This will only work if your string is long enough to allow you to

make the knot without pulling it through the string hole. You may

not understand what I'm talking about, but if it happens to you,

I think you'll understand.

- You may not need to use string ends for the higher gauge strings

(lower sounding strings) like from .045, .050, .055 etc. Follow directions

on the string

tying for lower gauges.

- Another thing you can use for a string end is leather shoelaces

cut into1 inch lengths. I have never tried toothpicks but I have

heard they would work. Also the sticks between the cotton of Q-tips.

In a pinch, you might need to get creative. Let me know if you come

up with some great idea.

String Tying

There

are many ways to tie harp strings and if you have one that you like,

you certainly can stick with it. This one I like because after you

cinch it up, the end stick doesn’t fall out as you’re stringing

your harp. Also, if you’re using Fuourocarbon strings, this knot

WILL hold.

If you have broken one of the larger gauge monofilament

strings (in the lower register), you will want to follow the directions

for string tying

for lower gauges.

So, to get

started, you will need the full length of string from your string package.

Then cut an inch long piece of a large gauge string, like .055. This

will be your end stick.

This video will show you step by step how to tie the string

with the instructions below for strings #1-22:

http://www.youtube.com/watch?v=JLslEP1t-b4

This video will show you step by step how to tie strings

#23-29 (see visual instructions here)

http://www.youtube.com/watch?v=lJCbXalHfDQ

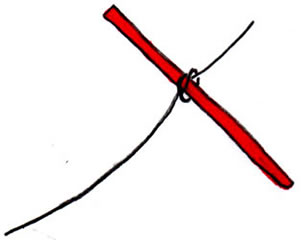

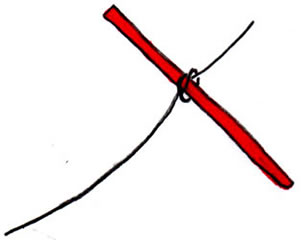

| Make a regular overhand knot and put your end stick (or string

tie) through the knot. |

|

| Pull it tight. |

|

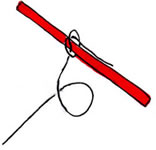

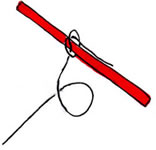

| Then make a loop as shown in |

|

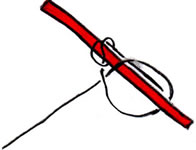

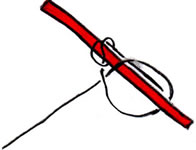

| Put it around the end stick that also includes the string

end. This is basically a half hitch. |

|

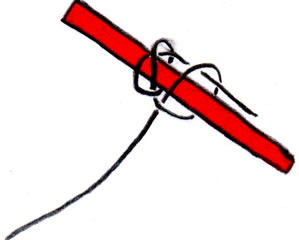

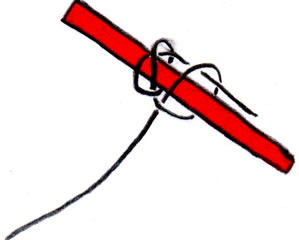

| Pull it tight and cut the end off if it’s longer than the

end stick |

|

You can then thread your string into the hole in the back

of the harp, through the lever and up to the tuning pin (see

the first helpful hint for an easier way).

Tying the string onto the tuning

pin

Now that you’ve got the knot tied at the end of the string, you’ll

need to thread it past the lever and through the tuning pin. Here’s

what I do to cinch the knot on this end. This works for all strings

but the bass wires (see below for these strings).

Line up the hole of the tuning pin so that it is vertical. Standing

behind the harp, thread the string through the hole (it should be

going straight up past the center of the lever and through the hole

in the tuning pin) and pull it back towards you.

Then slip the string below the tuning pin and between the wooden neck

of the harp and the string you just threaded up through the tuning pin.

You will be pushing the string toward the front of the harp now.

Bring it up between the tuning pin you’re stringing and the tuning

pin of the string one note below and pull it out away from the harp.

Begin tuning up the string. The first wind should catch around the

end of the string. Make sure your winds go toward the neck of the

harp as you tune (unless your pins are the type of pin that wants

you to make the winds go away from the neck. I believe Tripplet pins

are like this). Try to get a straight line from the tuning pin to the

bridge pin, especially in the bass wires.

Using the cutters of the needle nose pliers, cut off all of the extra

string to avoid any buzzing and to keep your harp tidy.

The Bass Wires

Pull the bass wire all the way through the tuning pin

straight up. Cut it off 3" above the tuning pin. Push

it back down so it is ALMOST flush with the tuning pin, just barely

sticking out (less than the width of the string). Begin winding the

slack around the tuning pin until you have it to pitch. This method

helps to cut down on sharp edges cutting you or your case. You can

see me demonstrating this on a video.

Robinson's Harp shop has this to say about the Bass wires: The Bass

wires are wound with a silver plated soft copper. Even though tarnished

bass wires don't affect the sound of your strings, you can

wipe them with any liquid silver cleaner and let them dry. The silver

plated soft copper is our only string material (except the blue and

red).

We have not tried this but if Sue Raimond at Robinson's says it works,

it must be OK. Let us know your experience if you try it.

Tuning up new strings

New strings will need to stretch before they will hold a pitch for

any length of time. You might want to over tune the string about 20-50

cents. This is a musical tuner measurement and 100 cents is a half

step. Then stretch the string a little bit. It will again fall way

below pitch. Do this a couple of times being careful not to stretch

or over tune it too much or it may break. If you are in the middle

of a performance, you’ll

need to get it to hold pitch before you play so keep talking to the

audience while you stretch and tune, stretch and tune.

I hope this has helped to get you on your way to tying harp strings.

If you have questions, come to one of my workshops at the next confernce,

visit our booth, or call me and I'll help you out. If you already have

a way that works for you, or if you find a better way, wonderful!

Trouble Shooting Some String

Problems

Continued String Breakage

If the string breaks continually at the point of contact with the tuning

pin, you might have a sharp edge where the string goes through the

hole. To compensate for this, you can leave about a 1/2-1 inch of

slack before tuning up the string. This eases the point where it

is sharp and usually takes care of the problem. And you can turn

the tuning pin over so the sharp edge is on the other side. There

is also some abrasive cord you can use like dental floss in the

tuning pin hole.There are 2 sizes and they cost $3 plus shipping

for both cords.

The same might be true for strings that break at the soundboard. The

bottom of the grommet may be cutting the string below the soundboard.

To help this situation, put a leather washer between your string knot

and the soundboard. You will need to put the washer on before you

tie the string. You can get leather washers from Robinson's String

Shop in California.Their phone number is 619 473-8556. If the string

is breaking right above the soundboard you may need a new grommet.

This is also available from Robinson's although you'll need to know

if your grommet is small, medium, or large and if it is regular or

heavy duty (they are not

interchangeable). not

interchangeable).

If your string pops off the

bridge pin (see photo to right)

If there are too many windings of the string on the tuning pin, it

may cause it to pop off the bridge pin. As the string stretches and

tunes up to pitch, you may acquire more windings on the tuning pin

than you want. The string is at too steep of an angle to the bridge

pin and when you lever that string, it pops off the bridge pin. The

solution is to unwind the string and push the windings away from the

neck until the string is going straight up from the bridge pin to

the tuning pin. If necessary, unwind the string completely and pull

it up through the tuning pin about 1/2 inch, re-wind the string and

tune it back up. Cut off the extra 1/2 inch of string. This should

take at least 1 winding out of the string and it should stay on the

bridge pin.

If your tuning pins slip

Sometimes a tuning pin will slip due to changes in humidity. Most tuning

pins are tapered like violin tuning pins. The pin gets larger in

diameter on the side that the tuning key fits into. If you have a

tapered tuning pin that keeps slipping, loosen the string about

half of a turn and then as you turn the pin to tune the string back

up, push the pin in. You should provide counter pressure by bracing

the neck of the harp with your left hand, while pushing in with the

key in your right. See a video of this here.

You can also check the angle of the string to the neck. If the string

angles towards the neck from the tuning pin, it could be putting back

pressure on the tuning pin and pushing it out of the hole. This is

more likely to happen in the low bass wires. The remedy here is to

loosen the string and stretch out the windings so they run straight up and

down instead of at an angle. If there aren't enough windings, you probably

have to put on a new string. Cut your string about 2" longer

than the string length you need to allow for the extra windings.

The picture on the

left is the wrong way.

The picture on the right is the

correct way.

With that said, if you are not

experiencing any problems, don't change anything. Just leave it alone.

The above tips and helpful hints are specifically taylored

for Thormahlen Harps.

Another really good video to watch on this topic is

from Steve Moss. Here is the link: https://www.youtube.com/watch?v=T_lxIj0OjyQ

For further and more information about strings, tuning,

and harp care, check

out Steve Moss’s videos at:

All

About Harp Strings

How

to Tune Your Harp, Part 1

How

to Tune Your Harp, Part 2

How

to Clean Your Harp

Tuning Pin Slippage

Hi Sharon

Just wanted to let you know I was sending you thanks as you helped

me re-string a broken string this afternoon. Katie had forgotten

to make a copy of directions for me and she suggested I check your

website. I was thrilled to see not only directions but drawings as

I struggled with that wiley string!!! The directions were clear,

I got the string on without breaking it and played just to make sure

that it stayed on. And yes, the Q tip stick worked great. I love my harp

(still!!) and appreciate it everytime I look at it. Paula Caron Grantham,

NH

Also see some suggestions on tuning

your harp, go back to the strings page

or go on to the page About Harps.

To

continue on the journey, find out more About

Harps in general. This is a very brief history. You'll also find

a "Parts of a Harp" diagram at the bottom of that page. To

continue on the journey, find out more About

Harps in general. This is a very brief history. You'll also find

a "Parts of a Harp" diagram at the bottom of that page.

|

not

interchangeable).

not

interchangeable).